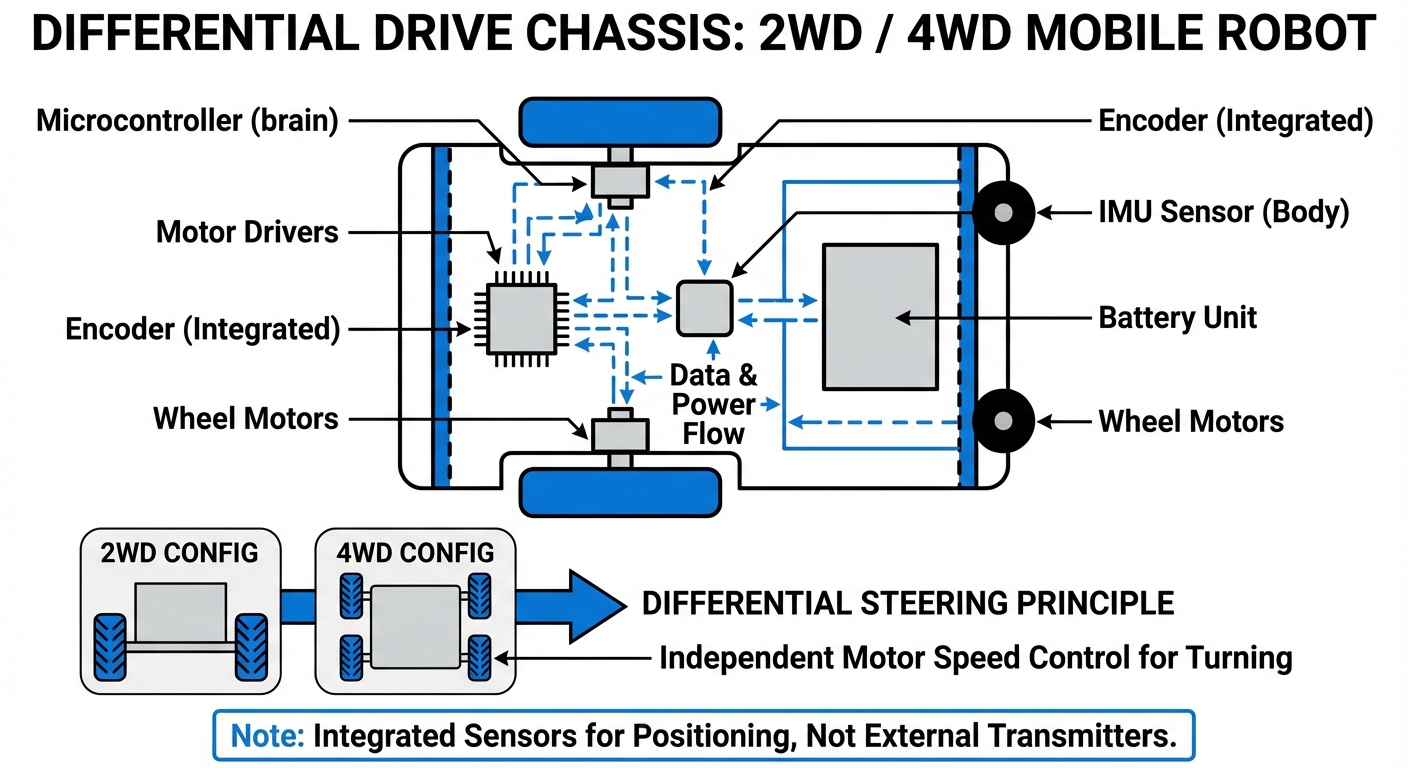

Differential Drive Chassis

The go-to setup for today's Autonomous Guided Vehicles (AGVs). Control two drive wheels independently for killer maneuverability, zero-turn radius, and rock-solid simplicity in indoor logistics and service bots.

Core Concepts

Zero Turn Radius

Unlike car steering, differential drives pivot on a dime. Spin wheels opposite ways, and it rotates right in place—ideal for cramped warehouse aisles.

Kinematics & ICR

Motion comes down to the Instantaneous Center of Rotation (ICR). The path is all about the speed difference between left and right wheels.

Stability & Casters

Two wheels alone are wobbly, so add passive caster wheels front or rear for stability without extra steering hassle.

Wheel Odometry

It leans on rotary encoders for position. Count wheel turns to figure relative position and heading, but watch for drift over time.

Power Efficiency

Against Mecanum or holonomic drives, differential is super efficient on energy. Direct traction, no wasted force, so batteries last through long shifts.

Simplistic Control

Control is simple PID—no fancy linkages or servos, keeping costs low and reliability high.

How It Works: The Mechanics

Like a tank but with wheels, the differential drive uses two motors on one axis. Motion is all about tweaking their speeds.

Straight Motion:

Turning:

Spinning:

This setup cuts failure points way down. No steering rack, tie rods, or fancy suspension needed for basic indoor AGVs.

Real-World Applications

Warehouse Fulfillment

Perfect for Kiva-style shelf lifters. Spin 360° under racks for dense storage and fast grabs in fulfillment centers.

Hospital Material Transport

AMRs hauling linens, meals, or meds use it to squeeze through tight hospital halls and elevators without big turns.

Commercial Cleaning

Floor scrubbers rely on it for exact cleaning paths, hugging walls and dodging obstacles with spot-on yaw control.

Manufacturing Line Delivery

Tugger AGVs shuttle parts between assembly lines. The simplicity keeps them running 24/7 in tough factories.

Frequently Asked Questions

What’s the biggest win of differential drive over Ackerman steering?

The biggest perk is the turning radius. Ackerman steering—like in a car—has a minimum turn limited by the front wheels' mechanics. But differential drive robots can pivot right in place with zero turning radius, making them way better for zipping through tight indoor spots and dead-end aisles.

How does wheel slippage affect differential drive robots?

Wheel slippage is a major headache for 'dead reckoning' navigation. If a wheel spins without budging the robot—like on a wet floor—the encoders still log the rotation, tricking it into thinking it's traveled farther or turned more than reality. That's why you need backup sensors like LiDAR or IMUs to fix the position.

Why are caster wheels necessary?

A two-wheel differential drive setup acts like a pendulum; it can't balance on just two points. Caster wheels add the third and fourth contact points for rock-solid static stability. They're passive and swivel freely to trail behind the main drive wheels.

Is differential drive better than Mecanum or Omni-wheel drives?

It really depends on your needs. Mecanum drives let you slide sideways, which differential ones can't. But differential drives win on cost, simplicity, higher load capacity, and efficiency since they avoid battling those vector forces in the wheel rollers.

What type of motors are best for this chassis?

Brushless DC (BLDC) motors paired with planetary gearboxes are the go-to industry standard. They deliver big torque at low speeds, pinpoint control, long stretches between maintenance, and smooth closed-loop speed control when hooked up with high-res encoders.

How do you calculate the robot's heading?

Heading comes from integrating the distance difference between left and right wheels over time, then dividing by the wheelbase. But this math model drifts over long hauls, so you fuse in a gyroscope or IMU for real accuracy.

What is the typical payload capacity?

Differential drive scales like a champ. Tiny educational bots handle under 1kg, while beefy industrial AGVs using it haul pallets up to 1,000kg or even 1,500kg—as long as the motors and chassis are beefed up right.

Can this chassis handle outdoor terrain?

Usually, no. Differential drive bots with casters shine on flat, smooth indoor floors. Outdoors, those little casters snag on cracks or gravel. For rough outdoor stuff, go with skid-steer (4WD) or tracked differential setups.

What is the "Wheelbase" and why does it matter?

The wheelbase is the distance between the two drive wheels' contact points. Wider ones mean better stability in turns but need more room to swing around. Narrower setups are nimbler but can feel twitchy at speed, making straight lines tougher to hold.

How do you handle motor synchronization?

No two motors are exactly alike, so same voltage to both means you'll veer in a curve instead of straight. PID controllers watch the encoders non-stop, tweaking voltage thousands of times a second to sync wheel speeds perfectly.

What safety sensors are compatible with this drive?

Since it spins in place, safety LiDAR scanners go on diagonally opposite corners (or two for full 360° coverage) to spot obstacles. Bumper switches and e-stop buttons are must-haves too for industrial safety rules.