Assembly Line Transport

Automate WIP transfers across your floor for smoother flow, JIT delivery, and staff focused on skilled work.

Why Automate Assembly Line Transport?

Maximized Throughput

No more manual jams—precise parts arrival keeps lines humming.

Enhanced Safety

Say goodbye to extra forklifts and lifts—our LiDAR and 3D cameras let robots navigate safely right alongside your team.

24/7 Operations

Our robots work around the clock without breaks or shift changes, unlocking true lights-out manufacturing and nonstop production.

Scalable Flexibility

Easily switch up routes through simple software updates—no magnetic tape or floor modifications required—as your production line evolves.

Accuracy & Traceability

Seamlessly connect to your MES for complete visibility into every move. Deliver the right parts to the right stations and slash assembly errors.

Rapid ROI

Drastically cut operating costs while ramping up output—you'll often see ROI in under a year.

Seamless Integration into Your Workflow

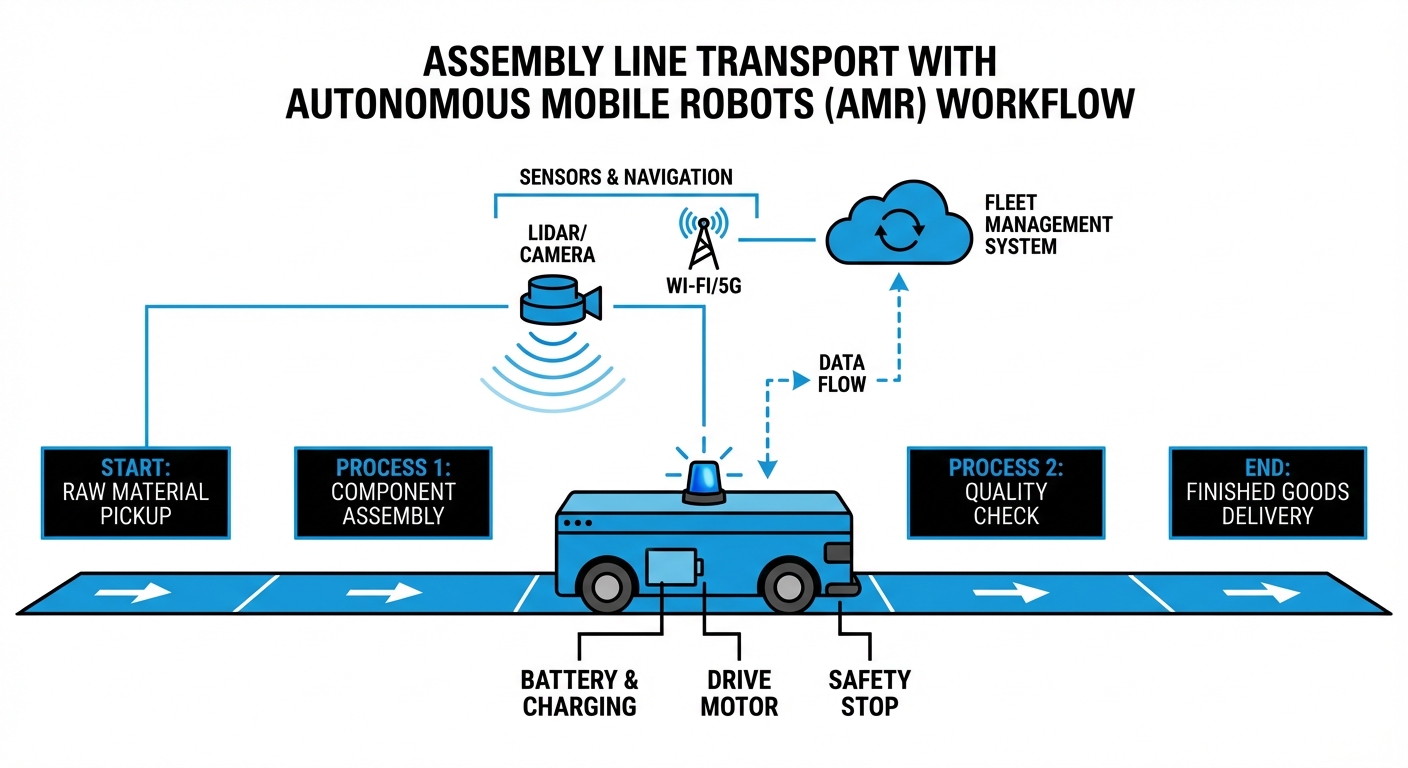

It all starts with mapping your space using cutting-edge SLAM technology. Then our fleet software plugs right into your MES.

When a workstation wraps up a job or needs more materials, the fleet manager alerts the nearest robot to grab sub-assemblies or fetch fresh parts from inventory.

Robots dodge obstacles on the fly and instantly replan their paths. They sync perfectly with conveyors for smooth handoffs or dock precisely for manual unloading.

Where It's Used

Engine & Chassis Assembly

Haul heavy engine blocks from machining to assembly without clunky fixed conveyors—model changes become a total breeze.

PCB & Component Transport

Transport delicate electronics in ESD-safe racks from storage to SMT lines, with super-smooth movements that minimize vibrations.

End-of-Line Packaging

Shuttle finished products from fillers to palletizers, preventing backups in your high-speed bottling lines.

Clean Room Logistics

Tackle material transport in ISO cleanrooms to slash contamination risks and keep bulletproof audit records.

What You Need

| Hardware Infrastructure | AMRs designed for payloads from 50kg to 1500kg, with versatile top modules like rollers, lifters, or racks. |

| Connectivity | Rock-solid Industrial Wi-Fi 6 or private 5G coverage across your entire facility for lightning-fast fleet coordination. |

| Environment | Smooth, level floors like concrete, resin, or tile work best. Keep aisles at least 20% wider than the robots, with dedicated charging spots. |

| Software Stack | Fleet server, navigation client, and REST API ready to integrate with your ERP, WMS, or MES. |

| Safety Compliance | Fully compliant with ISO 3691-4 standards for driverless vehicles, including comprehensive risk assessments. |